In the fast-evolving world of electronics manufacturing, understanding SMT meaning (Surface Mount Technology) and the fundamentals of PCB manufacturing is essential for delivering high-quality, reliable products. At PCBasic, we go beyond simply placing components and fabricating boards — we integrate advanced manufacturing processes, data-driven systems, and a lean production philosophy to deliver end-to-end excellence that supports customer success from prototype to mass production.

What Sets PCBasic’s Manufacturing System Apart?

While many factories focus purely on standard PCB assembly, PCBasic’s manufacturing system offers a broader, more integrated approach that ensures quality, consistency, and traceability across every project.

1. Full Lifecycle Manufacturing Capability

PCBasic doesn’t just assemble boards — we manage the entire lifecycle:

- Design for Manufacturability (DFM): Early design feedback to improve yield and reduce rework.

- Prototype to Volume Transition: Seamless scaling from prototypes to full production without sacrificing quality or timelines.

- Turnkey Solutions: One-stop services including parts sourcing, PCB fabrication, assembly, testing, and logistics.

This comprehensive capability ensures that whether your design has 10 boards or 100,000, the process is consistent and optimized.

2. Intelligent Use of SMT and Advanced Assembly Technologies

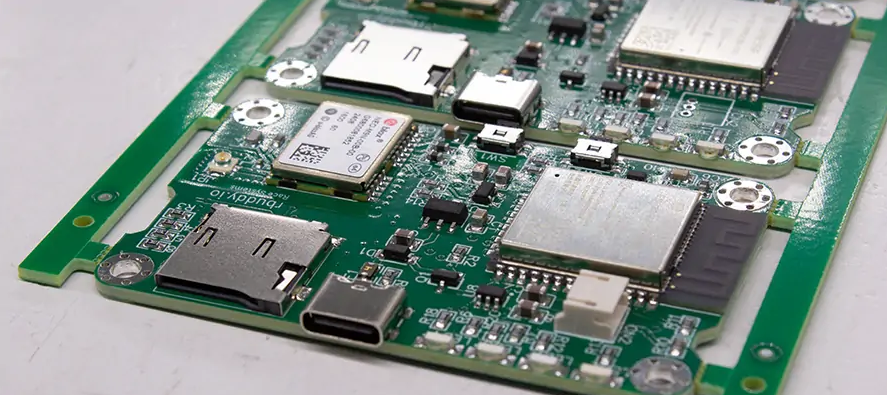

Understanding SMT meaning is fundamental to modern electronics assembly. PCBasic leverages cutting-edge SMT machines for rapid, precise placement of surface mount components — including 01005s, BGAs, CSPs, and other miniaturized parts.

Beyond SMT, we incorporate:

- Automated Optical Inspection (AOI): For real-time quality checks at multiple stages of assembly.

- X-Ray & SPI: Ensuring hidden solder joints (like BGAs) and paste deposition quality meet strict standards.

- Selective Soldering & Through-Hole: For boards requiring mixed assembly techniques.

This suite of technologies reduces defects, improves yields, and delivers consistent results across complex designs.

3. Integrated PCB Manufacturing and Assembly

While PCB manufacturing covers the fabrication of the board substrates themselves, PCBasic’s integrated system ensures assembled boards meet exacting specifications. By co-locating PCB fabrication and assembly, we reduce logistical delays, improve materials handling, and enhance overall quality control.

Benefits include:

- Traceable Material Flows: Every board, component, and batch is tracked and logged.

- Optimized Production Scheduling: Coordination between PCB fabrication and assembly lines minimizes lead times.

- Consistent Quality Standards: Unified quality procedures across both departments.

4. Data-Driven Quality and Lean Production

Our manufacturing execution system (MES) captures real-time data from each production step — from stencil printing metrics to final test results. This data becomes the backbone of continuous improvement:

- Defect Trend Analysis: Catch patterns before they become systemic issues.

- Yield Optimization: Fine-tune process parameters using historical performance data.

- Audit-Ready Traceability: Complete records for compliance, certifications, and customer reporting.

Coupled with lean principles, this leads to faster cycle times, lower waste, and predictable delivery performance.

5. Proactive Supply Chain & Component Management

PCBasic’s supply chain team works globally to secure authentic, high-quality components at competitive prices. This includes:

- Multi-Source Strategy: To avoid shortages or single-vendor dependencies.

- Real-Time Inventory Control: FIFO, batch tracking, and anti-counterfeiting checks.

- Supplier Quality Assurance: Verification of incoming material to ensure conformance.

This proactive stance ensures fewer production interruptions and consistent quality across all projects.

Why It Matters to Customers

What separates PCBasic from standard PCB assembly providers is not just the technologies we use, but how we tie them together into a cohesive, customer-centric manufacturing system:

- Reduced Time to Market: Faster ramp from prototype to production.

- Higher Reliability: Fewer defects, better performance in end applications.

- Scalable Solutions: Support for startups, mid-size OEMs, and large-scale manufacturers.

- Clear Communication: Production status, test results, and quality reports delivered transparently.

Conclusion

PCBasic’s manufacturing system transcends traditional PCB assembly — combining advanced SMT processes, integrated PCB fabrication, data analytics, quality traceability, and proactive supply chain practices into a unified, high-performance platform. Whether you’re designing cutting-edge consumer electronics, industrial control systems, medical devices, or IoT modules, PCBasic is engineered to deliver reliability, speed, and value beyond expectations.