In the world of architectural interiors and custom joinery, there’s a quiet truth most outsiders miss.

The real value of a seasoned millwork drafter isn’t flashy design concepts or artistic sketches, it’s the obsessive attention to details that most people never see.

To business owners, architects, engineers, and construction decision-makers across the UK and globally, this might sound counterintuitive. After all, isn’t design the hardest part?

Experienced millwork professionals will tell you otherwise.

As projects grow more complex, budgets tighter, and timelines shorter, details not design ideas are what determine whether a millwork project succeeds or fails. This shift is reshaping how custom millwork drafting, CAD workflows, and collaboration between millwork engineers and designers operate in today’s construction landscape.

Let’s explore why experienced millwork drafters deliberately spend more time on details and why that mindset is becoming a competitive advantage in the USA, UK, and global markets.

What Does a Millwork Drafter Really Do Beyond Design?

At a glance, many assume millwork drafting is about turning design concepts into drawings. In reality, that’s only the surface.

An experienced millwork drafter is responsible for translating design intent into buildable, manufacturable, and installable instructions.

That means accounting for:

- Material tolerances

- Joinery methods

- Hardware integration

- Site conditions

- Manufacturing constraints

- Installation sequencing

Design answers what it should look like.

Detailing answers how it actually gets built.

In modern millwork drafting services, especially on high-value commercial and residential projects, over 70% of drafting time is spent refining construction details, not inventing new forms.

Why Are Details More Critical Than Design in Modern Millwork Projects?

1. Because Design Errors Are Cheap Detailing Errors Are Expensive

Changing a design idea in CAD costs almost nothing.

Fixing a detailing mistake after fabrication starts can cost thousands.

According to a McKinsey construction productivity report, poor coordination and documentation errors contribute to up to 30% project cost overruns in construction projects worldwide.

Experienced millwork drafters know that:

- A 2 mm clearance error can ruin a full cabinetry run

- A missed edge profile can break design continuity

- Incorrect hardware specs can delay site installation by weeks

That’s why seasoned professionals slow down at the detailing stage because that’s where risk lives.

How Has Custom Millwork Drafting Evolved in the Last Decade?

Ten years ago, millwork drafting was often linear:

Design → Draft → Fabricate → Install

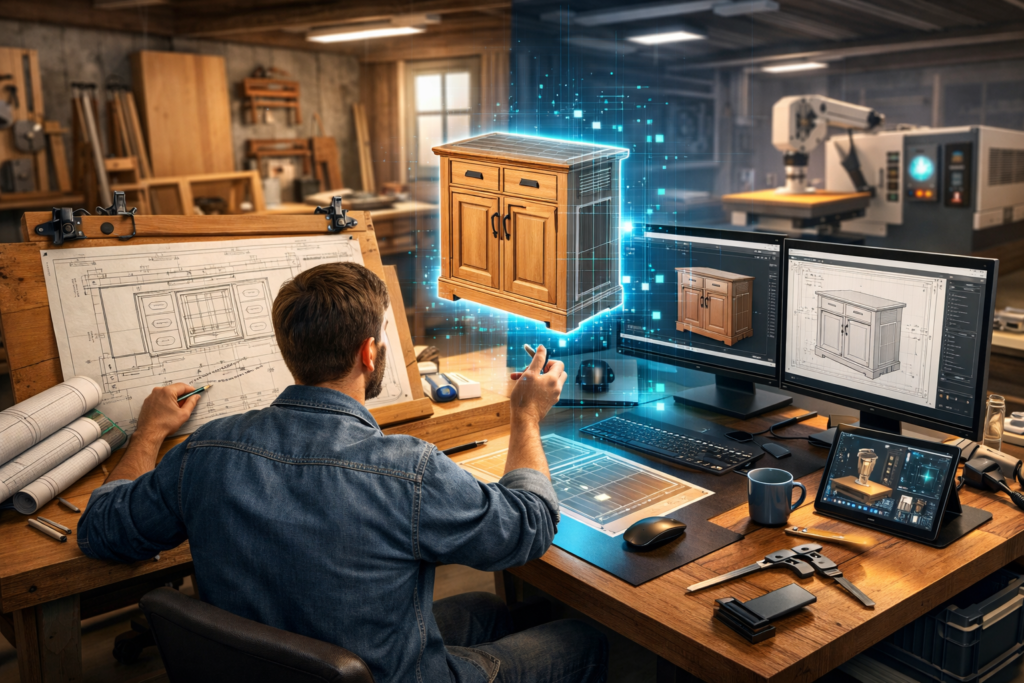

Today, it’s collaborative, data-driven, and iterative.

Key industry shifts include:

- Advanced CAD and BIM integration

- CNC-ready shop drawings

- Digital coordination with MEP and architectural models

- Higher client expectations for precision finishes

Autodesk reports that BIM-based detailing reduces rework by up to 40% when used correctly.

This evolution means millwork engineers and drafters now act as technical problem-solvers, not just drawing technicians.

And problem-solving happens in the details.

Why Do Experienced Millwork Drafters Question Designs Instead of Blindly Drafting Them?

Junior drafters often focus on “making the drawing look right.”

Experienced ones ask harder questions:

- Can this joint actually be manufactured?

- Will this cabinet clear site tolerances?

- Does this veneer direction align with grain continuity?

- Is this hardware available in the specified lead time?

This critical thinking is what separates a CAD operator from a professional millwork drafter.

In global projects especially across the UK and USA experienced drafters often collaborate directly with:

- Architects

- Interior designers

- Millwork engineers

- Fabrication teams

Their role becomes preventative: spotting design risks before they reach the shop floor.

What Role Do Millwork Engineers Play in Detail-Heavy Drafting?

While designers focus on aesthetics, millwork engineers focus on performance, durability, and feasibility.

Experienced drafters sit at the intersection of both.

They translate engineering logic into precise drawings that account for:

- Load-bearing requirements

- Fixing methods

- Material expansion and contraction

- Fire and building code compliance

In the UK and US markets, stricter regulations and liability expectations mean millwork detailing must be technically defensible, not just visually appealing.

This is why experienced drafters spend more time aligning with millwork engineers than refining visual layouts.

Why Is Detailing So Important for CNC and Modern Fabrication?

Modern millwork fabrication relies heavily on CNC machinery.

CNC machines don’t “interpret” drawings, they execute them literally.

That means:

- Every hole location matters

- Every edge profile must be defined

- Every tolerance must be intentional

A study by Construction Industry Institute (CII) shows that fabrication-ready detailing can improve production efficiency by 20–25%.

Experienced millwork drafting services prioritize:

- CNC-ready drawings

- Clear annotation

- Standardized layer management

- Clash-free assemblies

Good design inspires.

Good detailing produces flawless fabrication.

How Do Details Reduce Site Delays and Installation Conflicts?

On-site millwork issues are among the most common causes of interior fit-out delays.

Typical problems include:

- Cabinetry not aligning with walls

- Service clashes behind panels

- Incorrect fixing methods for site conditions

Experienced millwork drafters anticipate these issues early by:

- Coordinating drawings with architectural and MEP layouts

- Including site-specific tolerances

- Detailing installation sequences

According to Dodge Data & Analytics, coordinated shop drawings reduce installation delays by up to 33% in interior construction projects.

This proactive mindset is why experienced professionals spend more time reviewing and refining details than redesigning layouts.

Why Do Clients in the UK and USA Expect Higher Detail Standards?

Global clients especially in the UK and USA are increasingly detail-conscious.

Why?

- Higher labor costs make rework expensive

- Stricter building regulations

- Premium expectations for finishes and longevity

In these markets, millwork drafting services are judged by execution accuracy, not conceptual creativity.

For architects and developers, this means working with millwork drafters who:

- Understand regional standards

- Follow best practices in shop drawing documentation

- Anticipate approval authority requirements

Detail isn’t optional, it’s a market expectation.

Is Spending More Time on Details a Competitive Advantage?

Absolutely.

Firms that invest in experienced millwork drafters consistently see:

- Fewer RFIs

- Faster fabrication approvals

- Smoother site installations

- Higher client trust

In an industry where margins are tight, reducing errors is more profitable than accelerating design.

This is why many global firms now outsource or partner with specialized custom millwork drafting teams who focus exclusively on precision and constructability.

What Opportunities Are Emerging for Detail-Focused Millwork Drafting?

The future favors detail-driven professionals.

Key opportunities include:

- BIM-integrated millwork detailing

- Modular and prefabricated interiors

- Sustainable material documentation

- Digital twin and asset lifecycle data

As construction becomes more industrialized, millwork drafters who master detailing not just design will lead the next phase of growth.

Final Thoughts:

Design gets attention.

Details get results.

For business owners, architects, engineers, and decision-makers across the UK and globally, understanding this distinction is critical.

An experienced millwork drafter knows that success isn’t about drawing faster it’s about drawing smarter, deeper, and more responsibly.

That’s why the most trusted millwork drafting services quietly invest their time where it matters most: in the details that protect budgets, timelines, and reputations.

As the CAD and construction industries continue to evolve, firms that prioritize experienced, detail-oriented drafting often supported by leading UK CAD design companies will be the ones delivering projects that don’t just look good on paper, but perform flawlessly in the real world.

FAQs

Why do experienced millwork drafters focus more on details than design?

Experienced millwork drafters understand that design ideas are only valuable if they can be built accurately. Details such as joinery, tolerances, materials, and fixing methods directly affect fabrication, installation, and cost. Focusing on details reduces rework, delays, and on-site errors, especially in complex UK and global projects.

What does a millwork drafter do beyond creating designs?

A millwork drafter converts design intent into precise, build-ready shop drawings. This includes custom millwork detailing, coordination with architects and millwork engineers, CNC-ready documentation, and installation sequencing. Their role ensures designs move smoothly from concept to fabrication.

How do detailed millwork drawings reduce construction errors?

Highly detailed millwork drafting helps identify clashes, tolerance issues, and manufacturing constraints before fabrication begins. This proactive approach minimizes RFIs, prevents costly material waste, and ensures smoother installation critical for high-end commercial and residential projects in the UK and USA.

Why are millwork drafting services important for custom interiors?

Custom interiors require exact specifications, unique materials, and precise finishes. Professional millwork drafting services ensure that custom cabinetry, wall panels, and furniture are accurately documented, engineered, and fabricated to match design intent without surprises on site.

What role do millwork engineers play in detailed drafting?

Millwork engineers ensure that designs meet structural, performance, and compliance requirements. Experienced millwork drafters work closely with them to incorporate load considerations, fixing methods, and material behavior into drawings, making the final output both beautiful and buildable.

Why is millwork detailing more critical in UK and USA projects?

Projects in the UK and USA face stricter building regulations, higher labor costs, and premium quality expectations. Detailed millwork drafting helps meet compliance standards, reduces installation risks, and protects project budgets making precision a necessity, not a luxury.

How does detailed millwork drafting support modern CNC fabrication?

CNC machines require exact data to operate correctly. Detailed millwork drafting provides precise dimensions, hole locations, edge profiles, and material specifications, enabling faster production, consistent quality, and fewer manufacturing errors in modern fabrication workflows.